CATALOGS PRODUCTS

Choose the Catalogue of your interest:

QUALITY & TECNOLOGY

At SNT Industriale, innovation is the engine of growth, and in a market constantly modifying, the ability of renew and innovate is appointed to be ever and ever important; it’s easy to understand how development (R&D) of new components gains a decisive role to maintain competitiveness and satisfaction of customers.

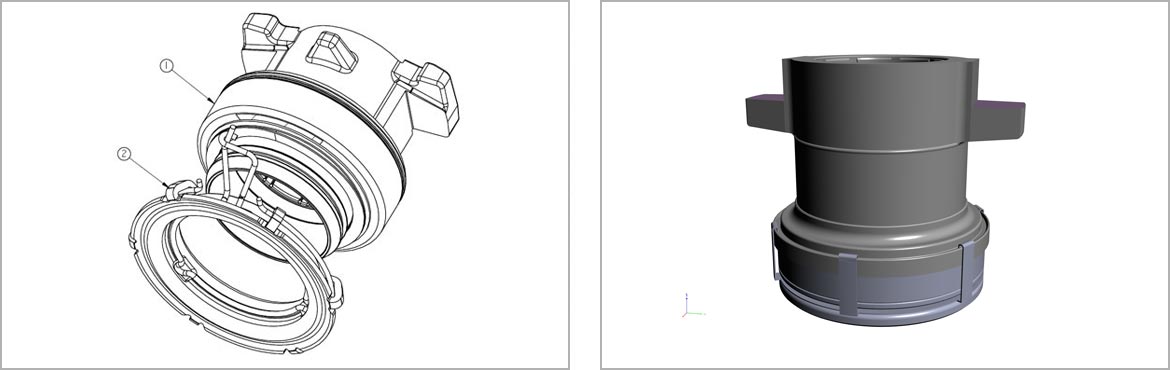

Our technical department handles all the phases of research and development process, starting from design in CAD 2D/3D to industrialization of the product through every level of manufacturing.

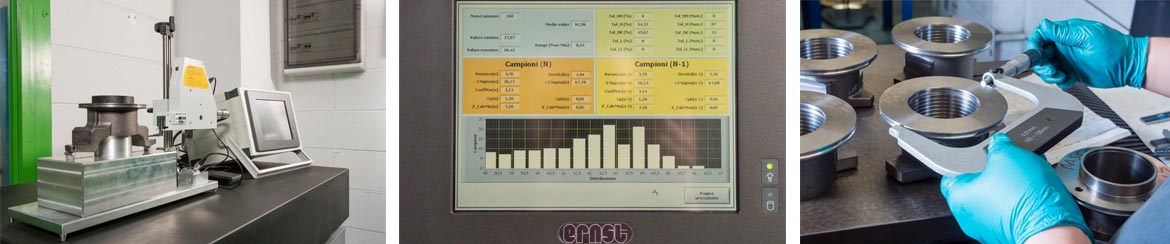

Furthermore, to achieve final approval and preventive homologation of new developments, it has been realized a quality room with a new control desk that allows us to test the releasers simulating real operations of the clutches on the vehicles, either with functional tests of vibrations, mechanical noise and temperature of the bearings, or durability tests that simulate the entire life of the bearing and verify their reliability even in extreme conditions.